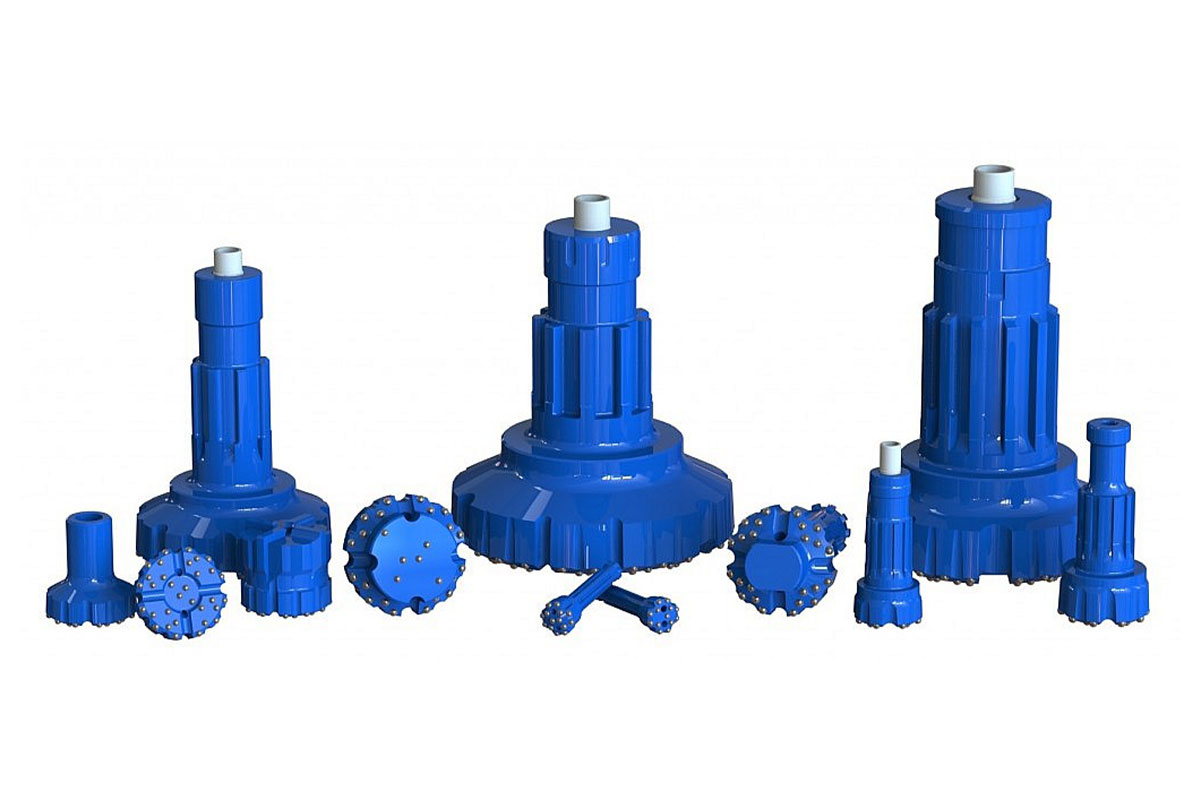

High-Quality DTH Standard Drill Bits

You Can Rely On

The production of drill bits for down-the-hole (DTH) hammers is a highly specialized process that combines precision engineering, advanced metallurgy, and rigorous quality control. These tools are essential in mining, construction, and oil and gas industries, where reliable and efficient drilling is critical.

GeoRocFor has been proudly designing and manufacturing high-performance DTH bits in Canada since 1990. Over three decades, we've developed exceptional technical expertise and deep industry knowledge, allowing us to deliver custom-engineered drilling solutions that meet the most demanding ground conditions. Trusted by professionals worldwide, GeoRocFor combines precision, durability, and innovation—bit after bit.

Where Expertise

Meets Precision

The process begins with the design phase, where engineers determine the optimal shape, size, and configuration of the drill bit according to its intended application and geological conditions. The choice of materials is crucial. High-grade alloy steels are commonly used for the bit body due to their strength, wear resistance, and toughness. Tungsten carbide buttons are selected for their hardness and ability to withstand high-impact forces.

The steel body is forged into a rough shape under high pressure and heat. This forging process increases the density and strength of the material. After forging, CNC (Computer Numerical Control) machines are used to achieve precise dimensions, create air channels, and prepare the bit for carbide button insertion. Precision machining ensures the proper balance and performance of the bit during operation.

Tungsten carbide buttons are pressed into pre-drilled holes in the bit face. The pattern and number of carbide buttons is calculated carefully to optimize penetration rate and tool life.

The entire drill bit undergoes a heat treatment process to enhance its mechanical properties. This step involves controlled heating and cooling cycles that increase the hardness and durability of the steel, making it more resistant to wear, impact, and fatigue during drilling operations.

After the heat treatment, the drill bit is cleaned and inspected. Surface treatments such as shot peening is applied to further improve wear resistance. Strict quality control measures including dimensional verification, hardness testing, and visual inspection ensure that each bit meets GeoRocfor performance and safety standards.