Engineered Crowns

Built to Last

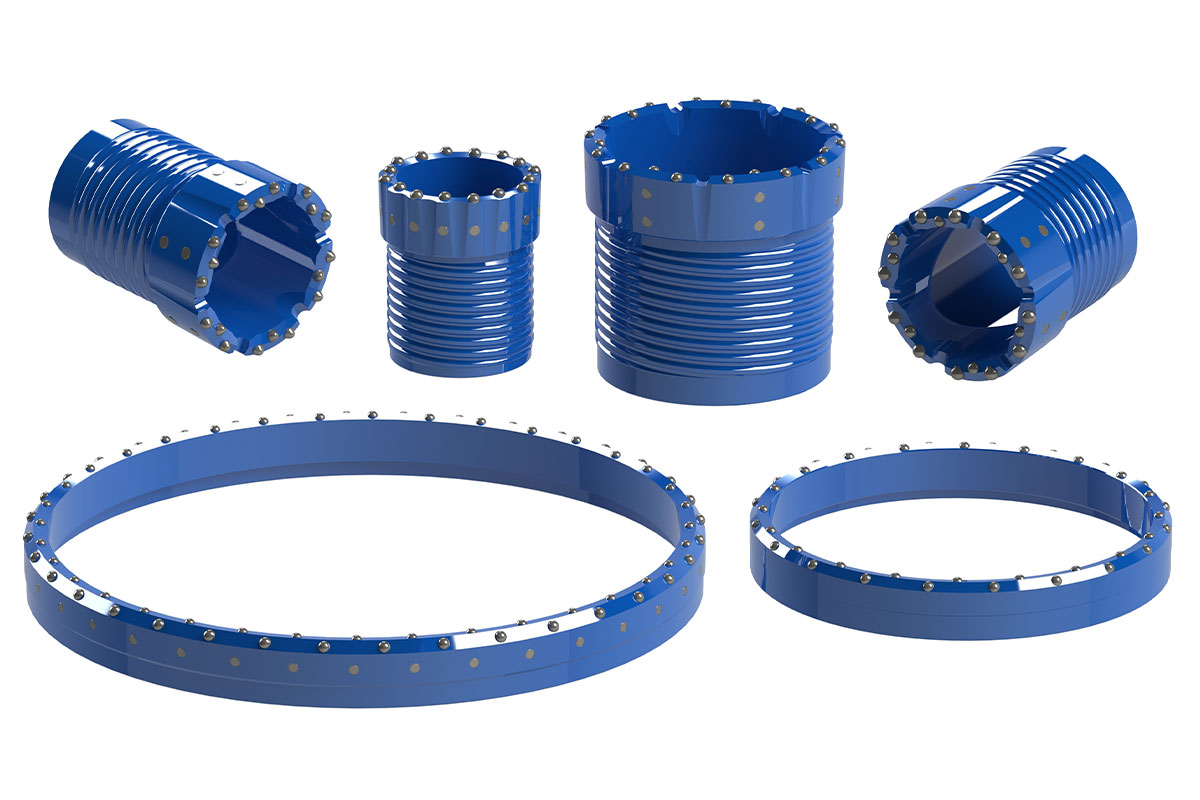

At GeoRocFor, we take pride in being a leading manufacturer of premium crowns for double rotation drilling, meticulously engineered to optimize your drilling operations. Our crowns, equipped with durable carbide buttons, are built for reliability, enhanced performance, and extended service life, even in the most demanding conditions. Whether you require single-use (permanent) models or reusable crowns, our products offer unmatched versatility, helping you achieve maximum efficiency and cost-effectiveness throughout your projects.

Our product range is designed to meet the diverse needs of the drilling industry. Whether you're engaged in large-scale construction or precision drilling, we stock the most popular sizes for quick delivery, ensuring that your operations stay on schedule. For more specialized applications, we also offer custom manufacturing services, tailoring each crown to fit your specific drilling requirements. This level of flexibility ensures that your equipment performs optimally in any geological environment, giving you confidence in every drill.

Versatile Crowns

for Every Drill

GeoRocFor's crowns are compatible with casings ranging from 4’’ to 30’’ in diameter, making them suitable for a wide range of drilling applications, from standard operations to large-scale foundation and mining projects. Our commitment to quality, innovation, and customer satisfaction means that you can rely on our products to deliver superior performance and longer-lasting results.

Engineered

for Excellence

Precision. Strength. Reliability.

When you choose GeoRocFor, you’re not just purchasing a product – you're investing in a partnership with a company that understands the challenges of the drilling industry. Our team delivers top-quality crowns for double rotation drilling, ensuring efficient, safe, and timely project completion. Let us be your trusted partner in achieving success with the best drilling solutions available.

Features:

- Alloy steel for high resistance

- Threads: single, double, or triple starts (Right or Left hand)

- Custom threads for perfect fit

- Buttons: round, conical, or ballistic

- Diameters: from 5’’ to 30’’

- Rapid availability for optimal responsiveness

Dr drilling

products

GeoRocFor manufactures welded drilling crowns with carbide buttons, designed to be welded directly to the end of the casing. These crowns are particularly useful for passing through the overburden (surface layers of soil) during drilling operations.

The carbide buttons provide wear resistance and cutting ability, enabling the crown to effectively cut through tough or abrasive materials encountered in the overburden. By welding the crown to the casing, it helps stabilize the borehole and prevents collapse during the drilling process, allowing for smoother drilling through challenging surface layers.

These welded drilling crowns are ideal for applications such as deep foundation work or water well drilling, where penetrating the overburden is essential. GeoRocFor's crowns are designed for durability and can be customized to meet the specific requirements of various drilling projects.

GeoRocFor manufactures threaded casing crowns equipped with carbide buttons, designed to be threaded onto the end of the casing. These crowns are specifically built to help penetrate the overburden (surface soil layers) during drilling, ensuring a more efficient and stable drilling process.

Made from the same alloy as standard drilling bits, the carbide buttons on the casing crown provide excellent wear resistance and cutting ability, enabling it to cut through tough or abrasive surface materials. The threaded design allows the casing crown to be securely attached to the casing, while also enabling easy removal and reuse.

One of the key advantages of these threaded casing crowns is their reusability. After drilling through the overburden, the crown can be recovered and reused in multiple drilling operations, making it a cost-effective solution for projects that require repeated drilling in challenging ground conditions.

GeoRocFor’s threaded casing crowns offer durability and flexibility, providing a reliable solution for projects such as foundation drilling or water well construction, where the overburden must be efficiently passed through to reach the target formation.

GeoRocFor manufactures drilling tubes specifically designed for use with double rotation drills. These tubes are equipped with nitrided tools at each end, which are welded to the central tube. This design significantly enhances the tube's durability and performance, ensuring a long service life even under challenging drilling conditions.

The nitrided tools provide excellent wear resistance, protecting the tube from abrasion and corrosion during the drilling process. This makes the tubes ideal for demanding applications, where extended lifespan and reliability are crucial.

GeoRocFor produces these drilling tubes to fit a wide range of thread types available on the market, with diameters ranging from 5'' to 24''. Whether you are drilling for construction, mining, or other heavy-duty projects, our tubes are built to meet the high standards of performance and durability required in double rotation drilling.

By manufacturing high-quality drilling tubes with nitrided tools, GeoRocFor ensures that your drilling operations are efficient, cost-effective, and can withstand the wear and tear of intense drilling activities.