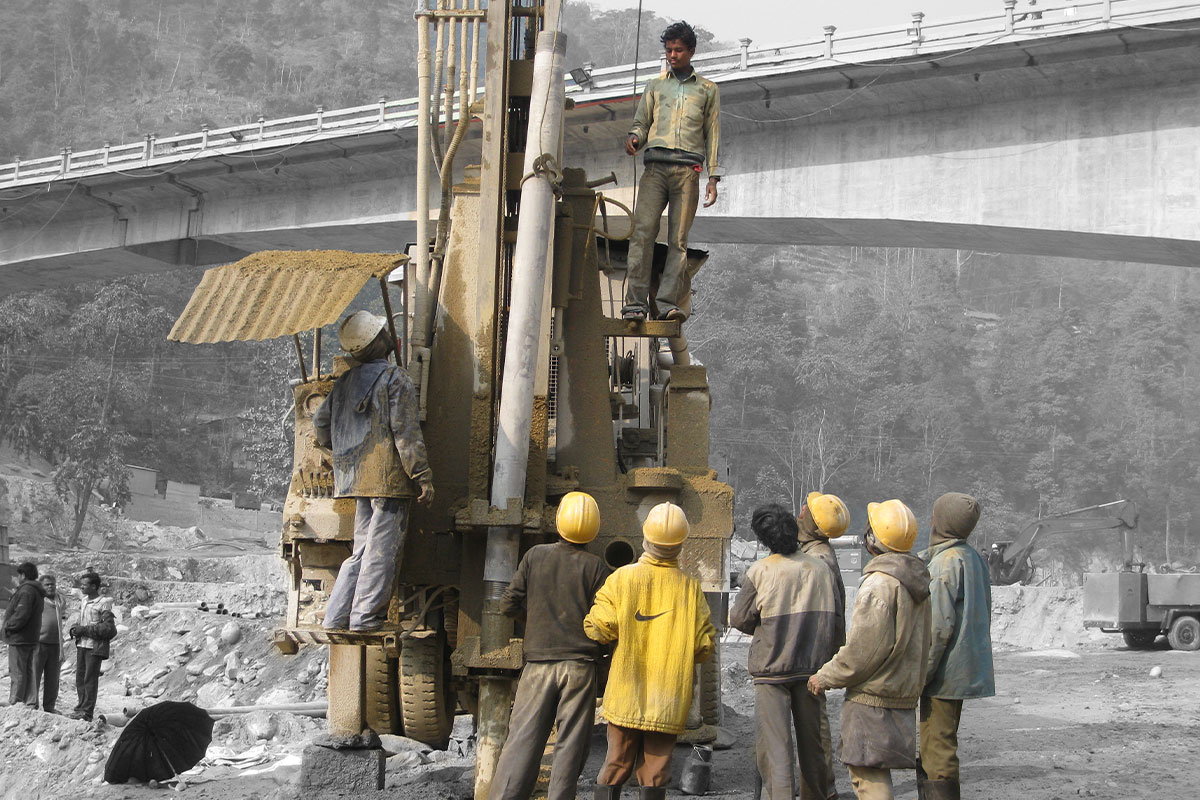

Foundations

An overburden casing system is highly beneficial in foundation drilling, particularly when drilling through unstable or loose surface materials such as sand, gravel, or clay. The primary purpose of the system is to stabilize the borehole during the drilling process, preventing the collapse of the borehole walls. This is especially important when drilling deep foundations, as it ensures the borehole remains open and aligned for the installation of foundation piles or other structural supports.

By installing the casing simultaneously with drilling, the system provides immediate support to the borehole, preventing the entry of loose material. This not only helps in maintaining the integrity of the borehole but also reduces the risk of contamination or erosion of surrounding soil. Additionally, the overburden casing system allows for safer and more efficient pile installation, ensuring that piles can be driven or drilled to the required depth without interference from unstable surface layers.

Drill Smarter

with AirMaster

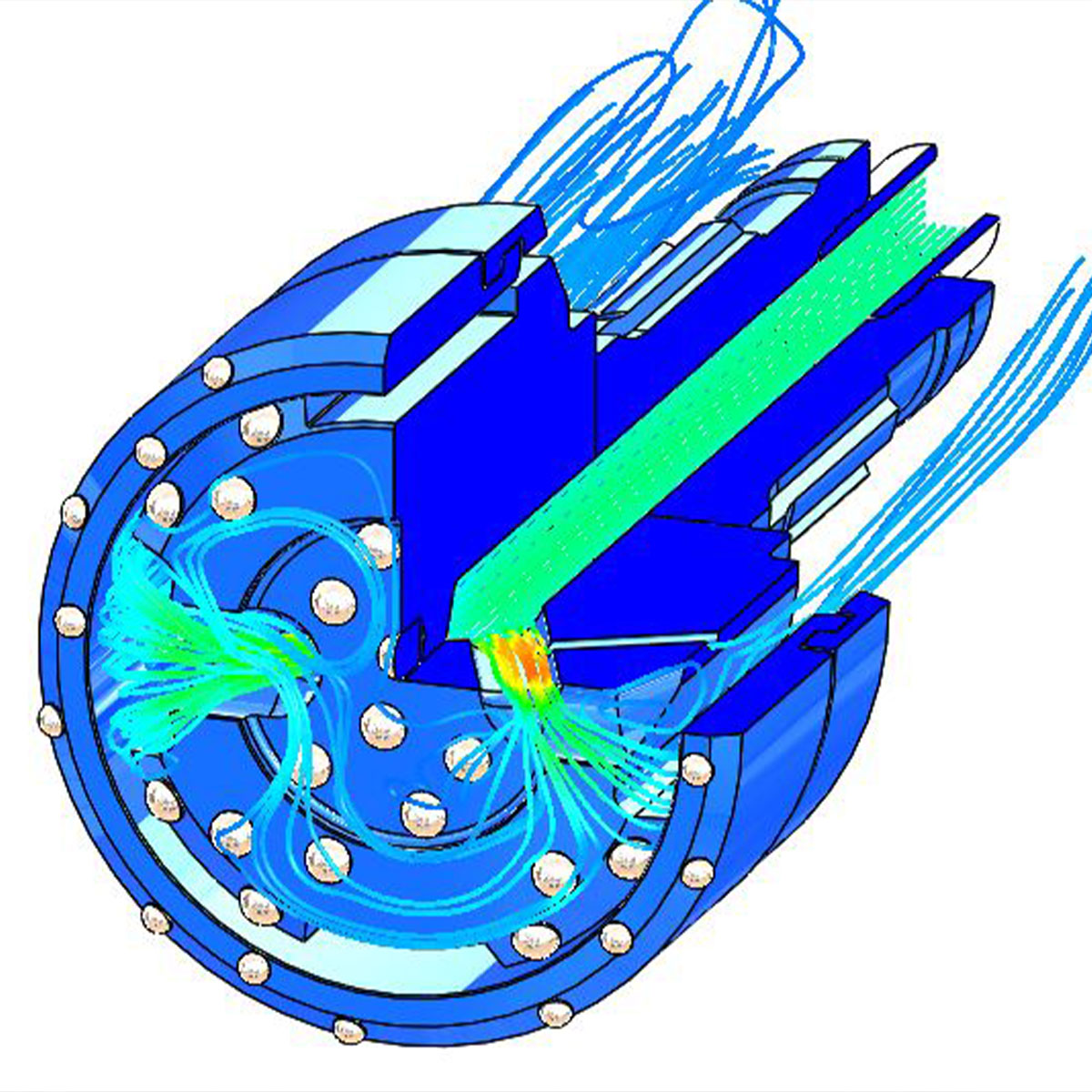

GeoRocFor now offers an innovative new system, the AirMaster, designed to significantly reduce the risk of air loss in the soil during foundation drilling, particularly when using an overburden casing system. Air loss is a common issue when drilling through loose or unconsolidated soils, or when air is used to clear the borehole. This can lead to inefficiencies, instability, and even the risk of borehole collapse. The AirMaster system addresses this by controlling and minimizing the escape of air throughout the drilling process.

By integrating the AirMaster system with the overburden casing, it helps to maintain stable pressure within the borehole, ensuring that air is efficiently contained and directed exactly where it's needed. This controlled environment reduces the risk of soil displacement, contamination, and unnecessary loss of valuable drilling resources, such as air.

Optimize Pile Drilling

with GeoRocFor Systems

Overall, the AirMaster system enhances the efficiency and safety of the overburden casing system by optimizing air usage, improving drilling performance, and creating a more stable and cleaner foundation drilling process. This leads to faster, more accurate pile installations while also minimizing the environmental impact of air loss in sensitive soil conditions.

GeoRocFor offers the best system adapted to pile drilling, micro piling and anchor drilling.

The GTE and GTE3 systems provide the ability to drill the socket under the crown with the same driver bit. This system is very advantageous since it saves a lot of time not having to handle the drill rods. When you remove the driver bit from the casing, the hole is finished.

Our

suggested systems

The Xs GTE system is especially designed for piling, micro piling, anchor installation...

The Xs GT system is especially designed for piling, micro piling, anchor installation...

The Xs F (Floating) system is especially designed for piling, micro piling...